Quality

Industrial quality products

No downtime

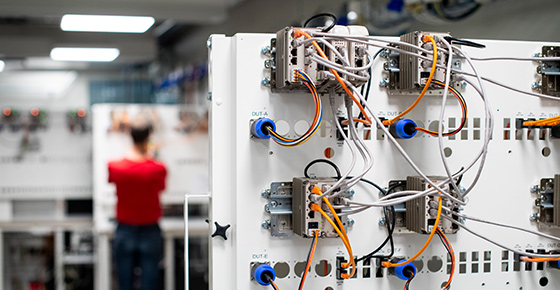

All equipment must be designed so that communication interference and downtime are eliminated. We achieve this by using high quality components, for example, capacitors with a long life and through validating designs in environments exposed to interference.

No maintenance

Our products are developed to withstand the harshest of environments without maintenance or service. In addition to the robust design, they never contain components that need to be replaced such as batteries.

Harsh environments

Industrial equipment is normally installed together with or in the vicinity of other equipment that generates interference, for example, welding equipment or heavy machines. We have more than 30 years of experience in designing communication equipment for industry and we use this know how in the development of industrial equipment.

Extended temperature range

An extended temperature range is frequently required in industrial applications. We guarantee functionality through the use of high quality components with an extended temperature range, this applies to hardware such as connectors.

Mechanical performance

In industrial applications equipment is often mounted on machines that move or vibrate. All our products are designed to withstand high mechanical stresses. As important as mechanical reliability is the mounting method, consequently our range comprises products for rack and DIN-mounting as well as table top or mini modem models.

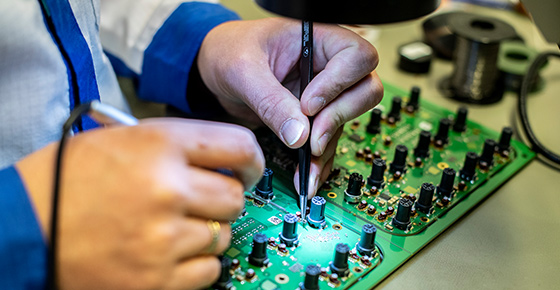

Manufacturing quality assurance

To ensure the highest levels of quality we carry out an array of tests and checks at many stages of the manufacturing process.

Software quality assurance

Unique testing processes developed and performed at our testing facilities in Sweden 24/7 makes it possible for us to deliver the best and most reliable software for our products.

Carl de Bruin

International sales

For support inquiries, click here to contact Technical Support